|

|

Center for NanoFabrication

Syntheses

Access

Safety

Cleaning procedures |

The Center for NanoFabication consists of two units:

- The Clean Room (located on the ground level)

- Synthesis (located on the third floor)

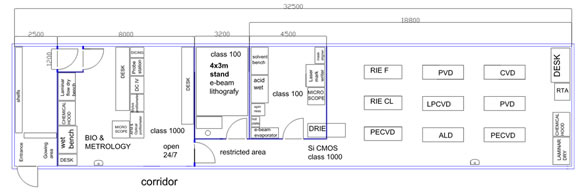

The Clean Room is subdivided into technical spaces and working areas of

an increasing cleanliness class. The room occupies three levels, of which

only one is accessible to the users. The following figure is a diagrammatic

plan of the level which contains the equipment grouped into two zones

according to the type of process. The first zone, with 55 square metres of

clean room space, is class 1000 dedicated to Bio & Metrology. The second

zone is a SI-CMOS area which consists of 154 square metres of clean space

class 100. The operation of such a clean room resorts to heavy

infrastructure that ensures the optimal conditions for air (filtration,

temperature, humidity, pressure) and water, as well as the supply and the

treatment of the waste chemicals (solid, liquid, gas). Other equipment, such

as the Focused Ion Beam and the parylene coating machine (Chemical lab), is

available outside the Clean Room.

The Clean Room is equipped with building vacuum, nitrogen, argon, DI water

and oxygen. Exhaust lines are connected to scrubbers; e-beam lithography

with class 10 mini-environments; E-beam ablation lithography; wet processing

for substrate cleaning and wet chemical etching; thin-film deposition on

metals and isolators; dry etching for material removal using reactive gases;

thermal processing for oxidation, annealing and vapor phase deposition;

diamond deposition; backend processes including plating, lapping/polishing,

dicing and bonding; processes, most of which will be semiconductor-based

(silicon, III/V), and will be conducted on materials similar to those used

in standard semiconductor technology, such as silicon, metals, isolators,

polymers, organics and oxides.

Site plan of clean space (ground level)

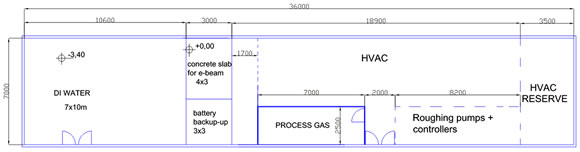

Technical section (bellow clean space)

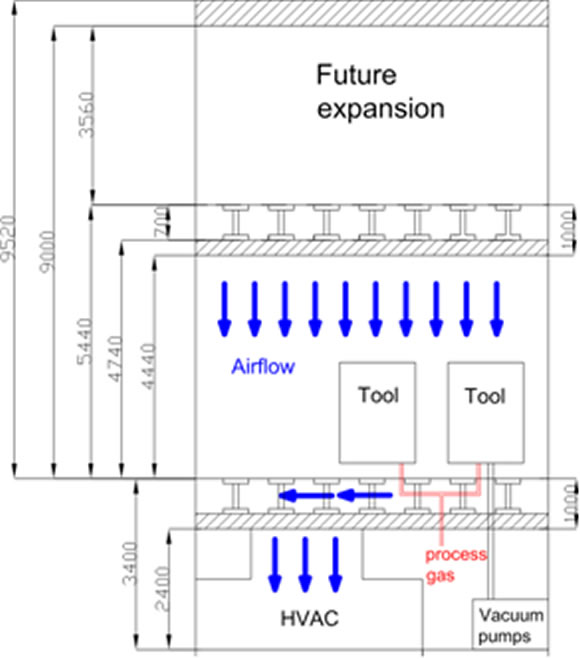

Below is cross-section view of CleanRoom.

Syntheses

The Centre for Nano Fabrication’s Chemical laboratory provides various

technologies for the synthesis of nano-phase materials including, but not

limited to Chemical Vapor Deposition, Atomic Layer Deposition, Physical

Vapor Deposition, pulsed micro-plasma cluster source, etc. The laboratory,

equipped with a double door entrance and an emergency exit, is located on

the third floor. Due to the nature of the facility, its air-condition system

is separated from the AC system for the rest of the building. The wet-hood

exhausts are connected to the scrubber.

The main

facilities are:

-

Furnaces for CVD

-

In

house made ALD

-

Pulsed

Micoplasma Cluster Source

-

Flame

Beam Source

-

Thin

Film Deposition

-

Glove

Box for inorganic materials

-

Fume

hood with Spin coater/Ultrasonic

-

Bath

-

Fume

hood for wet chemistry

-

Incubators for bio-samples

-

Two

Refrigerators

|

|

![]()

![]()